Screen Printing with a $10,000 Budget

Screen Printing with a $10,000 Budget

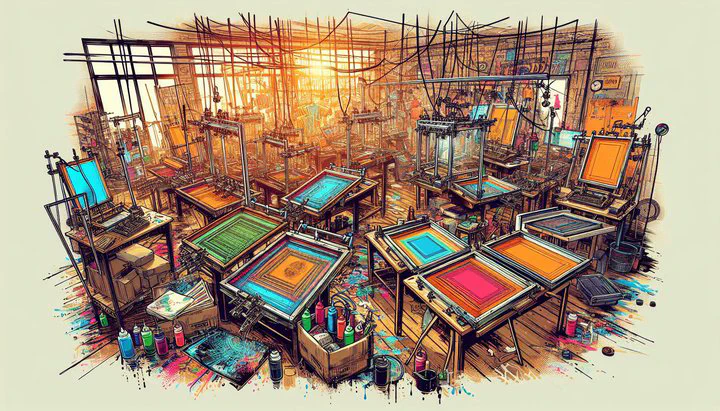

Starting a screen printing business is an exciting endeavor, especially when you’re working with a $10,000 budget. Whether you’re a seasoned designer or a creative enthusiast, setting up your own screen printing shop can open up a world of possibilities. In this guide, we’ll walk you through the essential steps to make your investment count.

Setting Up Your Screen Printing Shop

Are you ready to kickstart your screen printing dreams with a $10,000 budget? Setting up a screen printing shop can be exciting, but choosing the right equipment is key to getting the most bang for your buck. Let’s dive into the essentials you need to set up your shop and make cost-effective decisions to stay within your budget.

First, you’ll need a screen printing press. This is the heart of your operation. A good-quality manual press can cost between $1,000 to $2,000. If you’re looking to save, consider purchasing a used press that’s still in good condition. Next on the list is an exposure unit, which helps transfer your designs onto screens. You can find a basic unit for around $1,500. Don’t forget the **dryer**, which cures the ink on your prints. A conveyor dryer is ideal for t-shirts and can be found for about $2,000. If you’re tight on cash, a flash dryer might be a more affordable starting point.

Screens and squeegees are also crucial. Invest in a variety of screen mesh counts to handle different types of prints. A set of screens might cost you around $300. As for squeegees, a few different sizes will serve you well, and they typically cost about $10 to $20 each. Remember, finding deals on these items or buying second-hand can stretch your dollars further. Check online marketplaces or local classifieds for great bargains.

When deciding what to buy first, think about what will give you the most versatility and efficiency right away. If you’re planning on screen printing with a 10000 budget, knowing where to allocate your funds is crucial. Your budget should cover the essentials, but consider what you absolutely need to start printing right now. As your business grows, you can reinvest profits into additional equipment.

With these tips, you’re on your way to setting up a screen printing shop that’s both functional and budget-friendly. By making smart purchasing decisions, you can maximize your $10,000 budget and start printing high-quality designs in no time. You’re not alone in this journey. Many designers have started with a similar budget and found success.

Choosing the Right Ink for a Vintage Look

Looking for that perfect vintage feel in your screen prints? Choosing the right ink is crucial to achieving that classic, worn-in look that so many people love. With a $10,000 budget, you want to make sure you’re investing in inks that can deliver the results you’re after.

There are a few main types of inks to consider: water-based, plastisol, and discharge ink. Each has its own unique qualities and can give your prints a different feel and finish. Water-based inks are popular for their soft feel and eco-friendly nature. They soak into the fabric rather than sitting on top, making them perfect for that vintage look. However, they can be trickier to work with, especially on dark fabrics, and often require additional equipment like a forced-air dryer.

Plastisol inks, on the other hand, are known for their vibrant colors and ease of use. They sit on top of the fabric, which can sometimes make them feel less vintage. But, you can use additives to give plastisol inks a softer feel, closer to that vintage vibe. They’re also more forgiving if you’re just starting out, as they don’t dry in the screen and have a longer shelf life.

For achieving a true vintage look, discharge inks are a fantastic choice. They work by removing the dye from the fabric and replacing it with the ink color. This results in a super-soft print that feels like it’s part of the shirt. However, they work best on 100% cotton and might require special handling and ventilation due to the chemicals involved.

When deciding what type of ink should we use for vintage feel or look, consider what materials you’ll be printing on and what equipment you have or are willing to invest in. Brands like Permaset, Matsui, and Wilflex offer great options in each category, so you can find the perfect ink for your needs.

Remember, testing different inks on various materials can help you achieve the perfect vintage style. With your $10,000 budget, investing in high-quality inks will ensure your prints look professional and unique, making your screen printing venture a success right from the start.

Expanding Your Printing Capabilities

So, you’ve got your screen printing setup ready, and you’re eager to expand your horizons. With your $10,000 budget, you can do more than just print on t-shirts. Let’s explore how you can adapt your setup to print on a variety of items like sweatshirts, tote bags, and even hats.

To start, printing on t-shirts and sweatshirts is quite similar. You’ll use the same press and screens, but you might need to adjust the pressure and angle of your squeegee to accommodate thicker fabrics. Sweatshirts, being bulkier, may require a bit more finesse to ensure even ink distribution. Always test a sample to perfect your technique and avoid costly mistakes.

When it comes to tote bags, the key is using the right platens or attachments. Tote bags often have seams and handles that can interfere with smooth printing. A specialized platen that fits inside the bag can help you achieve a clean print. This investment is worth considering if you plan to offer tote bags as a regular product.

Hats can be a bit more challenging due to their shape. However, don’t worry! With the right attachments, such as a cap platen for your press, you can easily print on hats. You may also need a special curved screen or a heat press if you’re using heat transfers. Printing on hats can open up a whole new market and give your business an edge.

If you’re pondering, “What would you buy in our position with 10k?” consider investing in these versatile attachments. They will enhance your capability to print on a range of items, making your business more competitive. While it might be tempting to buy more inks or screens, expanding your capabilities can also expand your customer base.

By making smart choices and investing in the right equipment, you can ensure that your $10,000 budget goes further, allowing you to offer a wider range of products. This versatility not only maximizes your investment but also keeps your business dynamic and appealing to a broader audience.

Call to Action

Ready to get started? Check out our community subreddits for more tips and connect with fellow screen printers. Share your experiences and learn from others who have successfully set up their screen printing businesses with a $10,000 budget.