Tips for Standardizing Screen Printing

Tips for Standardizing Screen Printing

Are you looking for tips for standardizing screen printing in your business? You’re in the right place! Standardizing your screen printing process not only improves efficiency but also enhances the quality of your products. Let’s dive into some practical strategies to help you achieve consistency and excellence in your screen printing projects.

The Importance of Consistent Print Placements

In the world of screen printing, consistent print placements are key to delivering high-quality products that keep your customers coming back. Imagine receiving a shirt where the logo is slightly off-center or a hoodie with a design that doesn’t quite line up on the sleeve. These little inconsistencies can make a big difference in how your customers perceive your work. When you standardize print placements across different garments, you ensure that every item looks just right, boosting your brand’s image and customer satisfaction.

Why does consistency matter? For starters, it helps maintain a professional appearance across all your products. When a customer buys from your brand, they expect a certain level of quality. Inconsistent prints can harm your reputation and make your work look less polished. Consistent placements also simplify the process for your team, reducing errors and ensuring that every item that leaves your shop meets the high standards you’ve set.

Let’s look at common placement issues. Sometimes, designs are printed too high or low on a shirt, or a sleeve print isn’t placed symmetrically. These mistakes can happen easily if you don’t have a standard process in place. By setting up a system to standardize print placements across different garments, you can avoid these pitfalls. Use tools like rulers, placement grids, or digital software to mark exact spots for each design. This way, every print is in the perfect position, every time.

In the end, having consistent print placements not only enhances your final product but also builds trust with your customers. They know that they can count on your brand for quality and precision, which encourages repeat business and positive word-of-mouth. So, make sure to invest time in developing a solid plan for your print placements. It’s a small step that can lead to big rewards for your screen printing business.

Creating Clear Guidelines for Screen Printing

Creating clear guidelines is essential for achieving top-notch results in screen printing. One of the first steps in this process is defining print zones and sizes. But what exactly does this mean? Simply put, print zones are the specific areas on a garment where designs can be placed, while sizes refer to the dimensions of the design itself. By establishing these boundaries, you can ensure that your prints are not only consistent but also visually appealing.

To get started, sit down with your team and map out common garments you print on, like t-shirts, hoodies, or bags. For each item, decide on standard print zones where designs will look best. For example, the chest area of a t-shirt or the center of a tote bag. Then, determine the sizes that work best for these zones. Remember, a design that looks perfect on a small shirt might not fit as well on an extra-large one. Having clear guidelines like print zones and sizes helps you maintain uniformity across different products and sizes.

Once you’ve defined these guidelines, it’s important to document them clearly. Create a guide or a handbook that your team can easily refer to. This should include illustrations and examples for each type of garment you work with. The benefits of having standardized guidelines go beyond just your team; they also help your clients understand what to expect. When clients know the exact specifications you work with, it builds confidence and trust in your services.

Moreover, clear guidelines reduce errors and improve efficiency. When everyone on your team knows exactly where and how big a design should be, it minimizes the chances of mistakes. This not only saves time but also reduces material waste. So, invest time in setting up these guidelines, and you’ll see a significant improvement in your screen printing operations. By creating a system that everyone can follow, you ensure that every print meets your high standards.

Utilizing Visual Guides and Templates

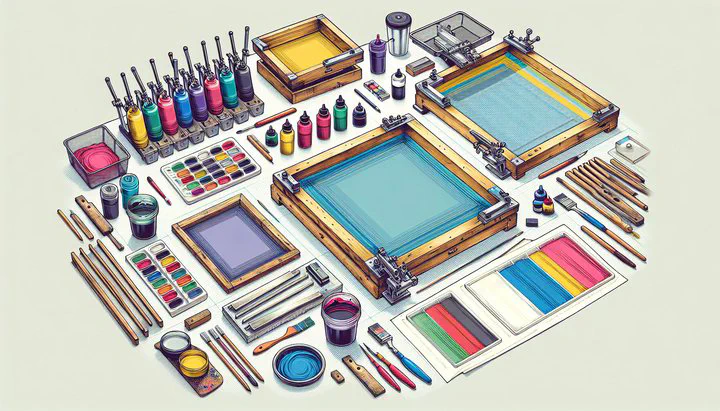

To make your screen printing process smoother and more reliable, consider using visual guides, templates, or systems. These tools can be game-changers when it comes to achieving consistent results and maintaining high standards in your work. But what exactly are they, and how can they help you standardize your process?

Visual guides are like roadmaps for your designs. They can include printed templates, digital layouts, or even physical rulers and grids. These guides help you see exactly where your design will be placed on a garment before you start printing. For instance, using a template ensures that logos are always centered on the chest or that sleeve designs are placed at the same height on every shirt. By incorporating these tools, you can easily standardize print placements across different garments and avoid common mistakes.

Creating your own templates isn’t as hard as it sounds. Start by measuring and marking the areas where you frequently print designs. Use these measurements to create digital templates in software like Adobe Illustrator or Photoshop. Adobe Illustrator and Photoshop are popular design software used for creating digital templates. You can also print out these templates and use them as physical guides in your printing setup. This way, you always have a clear reference for where each design should go. Some printers even use digital systems to project guides directly onto the garment, which can be especially helpful for complex designs.

The benefits of using visual guides and templates go beyond just accuracy. They also speed up your workflow and make it easier for team members to follow the same process. When everyone uses the same system, it reduces the chances of errors and improves overall efficiency. Plus, when clients see the precision and consistency in your work, it builds trust and can lead to more business opportunities.

Incorporating visual guides into your screen printing process is a simple yet powerful way to enhance your operations. By ensuring that every print is placed perfectly every time, you boost both the quality of your products and the satisfaction of your customers. So, take some time to explore different types of visual aids and find the ones that work best for your business. It’s a small investment that can lead to big improvements in your screen printing results.

Implementing Scalable Solutions for Growth

As your screen printing business grows, it’s essential to implement scalable solutions that help maintain quality standards while allowing for expansion. But what does it mean for a solution to be scalable in the context of screen printing? Simply put, scalable solutions are strategies and tools that can grow with your business, accommodating increased demand without losing quality.

One effective strategy is to invest in automated equipment. While it might seem like a big expense initially, automated screen printing machines can handle larger volumes more efficiently than manual setups. These machines ensure that each print is precise, helping you standardize print placements across different garments even as your order sizes increase. Automation reduces human error, speeds up production, and allows your team to focus on creative tasks, improving both productivity and job satisfaction.

Another scalable solution is adopting a robust project management system. This can be as simple as using software to track orders, manage inventory, and schedule production runs. With a clear overview of your operations, you can make informed decisions about resource allocation and process improvements. A good system will keep everyone on the same page, ensuring that orders are completed on time and to specification, even as your business scales.

Consider case studies of screen printing businesses that have successfully implemented scalable solutions. For example, a small print shop might start by using basic templates and manual presses. As they grow, they might switch to automated presses and digital management systems. These changes allow them to take on larger contracts without compromising on print quality. By learning from these examples, you can find the right balance of tools and techniques that suit your business needs.

In conclusion, implementing scalable solutions for screen printing businesses is about preparing for growth while maintaining high standards. Whether it’s investing in automation, streamlining project management, or learning from others, each step you take will help your business thrive. By planning for the future and choosing the right strategies, you can ensure your screen printing operations remain efficient and successful as you expand.

We hope these tips for standardizing screen printing help you enhance your business. Remember, consistent quality leads to satisfied customers and repeat business. Feel free to share your experiences or ask questions in the comments below. We’re here to support your journey in the screen printing world!