Water Based Ink Drying Too Fast

Facing Fast-Drying Ink Frustrations? Here’s Help!

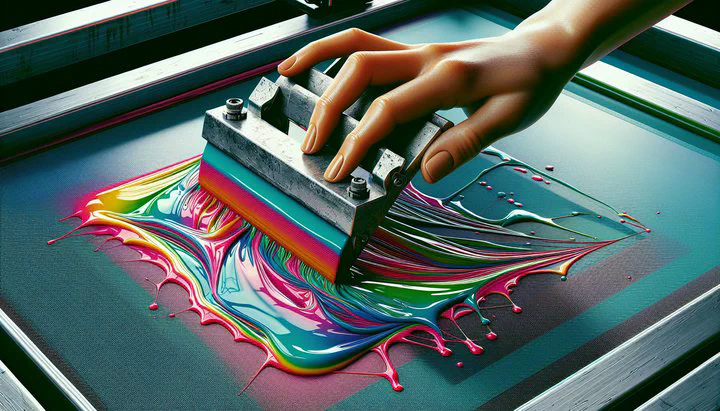

Are you finding that your water-based ink is drying way too fast during your screen printing projects? You’re not alone! This common issue can disrupt your creative flow and lead to less-than-perfect prints. But don’t worry—this article is here to help you understand why it’s happening and how to fix it, so you can get back to creating with confidence.

Understanding the Problem: Why Water-Based Ink Dries Too Fast

When you’re working on a screen printing project, have you ever noticed your water-based ink drying too fast? It can be pretty frustrating! This happens more often than you might think, and understanding why is the first step to fixing the problem.

First, let’s talk about temperature. Hotter conditions make ink dry to the screen super fast. If your workspace is on the warm side, it might be causing your ink to dry before you’re ready. This can lead to uneven prints and can be a real headache for your design process.

Next up, humidity plays a big role. If the air is too dry, it’s like a sponge soaking up all the moisture from your ink. Conversely, if it’s too humid, your ink might not dry at all! Finding the right balance is key to keeping your ink just right and avoiding those pesky drying issues.

Finally, consider the airflow in your workspace. Too much air movement can make your water-based ink drying too fast even worse. It’s like having a fan blowing over your ink, speeding up the drying process when what you really need is a pause button. By understanding these environmental factors, you can start to adjust your setup and prevent the ink from drying too soon.

The Consequences: Ink Flakes Off and Trouble Printing on Tissue Paper

When your water-based ink dries too fast, it can lead to some annoying problems. One of the most common issues is that the ink flakes off the material you’re printing on. This happens because the ink doesn’t have enough time to properly bond with the fabric or paper. Imagine spending hours on a design only to see bits of ink peeling away—it’s enough to make anyone frustrated!

Another tricky situation is when you’re trying to print on delicate materials, like tissue paper. If the ink dries to the screen super fast, it becomes difficult to achieve a smooth print. Tissue paper is thin and fragile, so it doesn’t take much for things to go wrong. The fast-drying ink can cause the paper to tear or the design to come out uneven, leading to a lot of wasted materials and effort.

Let’s hear from some designers who have faced these challenges. Sarah, a freelance screen printer, recalls a time when she was printing wedding invitations on tissue paper. “The ink kept drying too quickly, and I couldn’t get a clean print,” she says. “I had trouble printing on tissue paper because the paper would stick to the screen and ruin the design.”

These issues not only waste your time and materials but also add stress to your creative process. Understanding these consequences helps you see why managing how fast your ink dries is so important. In the next section, we’ll explore possible solutions and ask the question: should I try a different ink?

Solutions and Alternatives: Should I Try a Different Ink?

Dealing with water-based ink drying too fast can be a real challenge, but don’t worry! There are plenty of ways to tackle this problem and improve your screen printing results. Let’s dive into some practical solutions.

First, consider tweaking your environment. If your ink dries to the screen super fast because of a warm workspace, try cooling things down. You can use fans or air conditioning to lower the temperature. Just be careful not to point fans directly at your work area, as too much airflow might make the drying problem worse. Also, keeping a humidifier nearby can help maintain the right balance of moisture in the air, preventing the ink from drying too quickly.

Another handy trick is to use ink retarders. These are special additives that you mix into your ink to slow down the drying process. They can be a lifesaver for projects where you need more time to work on intricate designs or when printing on delicate materials like tissue paper. Just add a little bit at a time and test your ink to get it just right.

But what if these adjustments aren’t enough? That’s where the question arises: should I try a different ink? Sometimes, switching to a different type of water-based ink can make all the difference. Look for inks that are specifically formulated to dry slower, especially if you’re working in challenging conditions. There are many brands and types out there, so experimenting with a few can be a good idea.

Remember, the key is to find the right ink that suits your specific project and environment. By exploring these solutions, you can overcome the hassle of water-based ink drying too fast and get back to creating beautiful designs with confidence.

By understanding the factors that cause water-based ink to dry too fast and experimenting with these solutions, you can overcome the challenges and enjoy smoother, more successful screen printing projects. Have you tried any of these tips? Share your experiences with us on DesignResolve, and let’s support each other in tackling these common design hurdles!